Oct . 10, 2025 09:20 Back to list

Why Buy CE Certification 250 Micron Stainless Steel Mesh?

Field notes on CE certification and 250 μm stainless steel mesh

If you’re specifying filtration or safety screens for EU-bound equipment, you’ve likely typed ce certification 250 micron stainless steel mesh into a search box at least once. Same here. I’ve spent enough time in Anping, Hebei—the wire-mesh capital—to see what’s marketing fluff and what actually clears EU conformity checks.

What’s trending (and what buyers ask)

Three themes keep coming up: traceable 316/316L chemistry, documentation that plugs straight into CE technical files, and reproducible micronic accuracy. Many customers say they want “CE-certified mesh,” but, to be honest, CE marking applies to the finished machinery or construction product. The mesh supports compliance when it’s made to recognized standards and shipped with proper declarations and test data.

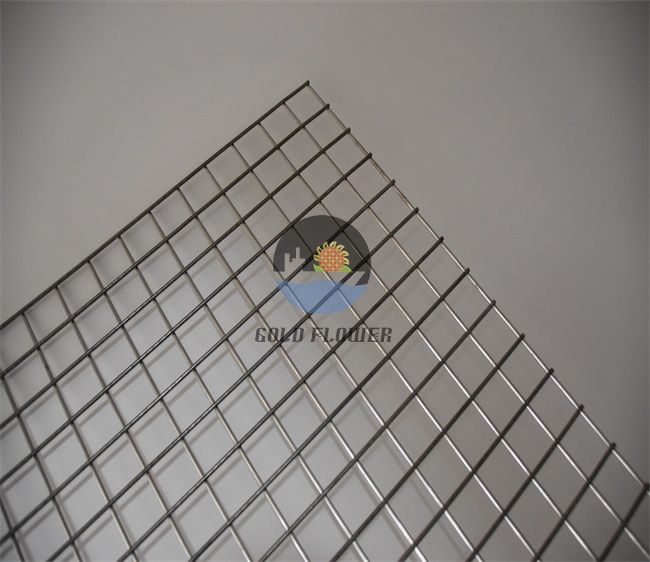

The product in focus

Origin: East Industry, Anping City, Hebei, China. The 316 Stainless Steel Wire Mesh Panel is a welded-panel format; for fine cut-points like 250 μm, suppliers (including this one) typically laminate or frame a woven 316 cloth (per ASTM E2016/ISO 9044) onto a 316 welded support. Types available also include galvanizing options (hot-dipped or electro) for carbon-steel counterparts—useful in non-corrosive enclosures.

| Spec | 316 Stainless Steel Wire Mesh Panel (≈250 μm) |

|---|---|

| Material | AISI 316 / 316L (EN 1.4401/1.4404), welded frame + woven cloth |

| Aperture (nominal) | ≈250 μm (real-world use may vary ±5–10% depending on wire dia) |

| Typical mesh count | Around 60 mesh (wire dia ≈0.17–0.20 mm) |

| Finish options | Pickled & passivated; galvanized variants for non-SS builds if needed |

| Standards | ASTM E2016, ISO 9044; material cert per EN 10204 3.1 |

| Service life | 3–10 years in typical food/pharma/chemical duty; environment-dependent |

How CE compliance is supported

For ce certification 250 micron stainless steel mesh used in CE-marked machinery or process equipment, buyers request: DoC referencing applicable directives (e.g., Machinery Directive for the machine), RoHS/REACH statements, material traceability, and test logs. Typical data snippets: salt spray per ASTM B117 > 500 h (no red rust on 316), bubble-point/flow tests for permeability, and dimensional checks vs ISO 9044 tolerances.

Process flow (quick but real)

- Material: 316/316L wire rod, heat/lot controlled.

- Wire drawing and weaving to target 250 μm aperture; welded 316 frame fabricated separately.

- Lamination or clamping of cloth to panel; edge finishing and deburring.

- Cleaning, pickling/passivation; optional electropolish.

- QC: aperture mapping, tensile/bend tests, visual per ISO 9044; corrosion test sampling (ASTM B117).

- Docs: EN 10204 3.1, RoHS/REACH, and test reports for your CE technical file.

Where it’s used

Food and beverage filtration, pharma granulation screens, solvent recovery, water pre-filtration, dust-collector guards, and electronics coolant strainers. One German OEM told me their CE review went faster once the mesh supplier provided ISO 9044 mapping and 3.1 certs—no drama.

Vendor snapshot (what to check)

| Vendor | Docs & Standards | Lead Time | Customization |

|---|---|---|---|

| East Industry (Anping) | EN 10204 3.1, ISO 9044, ASTM E2016; RoHS/REACH | ≈10–20 days | Panels, rolls, framed screens, custom edges |

| EU Distributor | Strong CE file support, premium price | Stock for common sizes | Moderate—mostly standard SKUs |

| Generic Trader | Varies; request samples and certs | Uncertain | Unclear; check tolerances |

Real-world snippets

- Spain beverage plant: swapped 304 for 316; CIP cycles increased service life from ~18 to ~36 months.

- Benchtop pharma granulator: 250 μm screens with electropolish cut product hang-up—unexpected but welcome.

Bottom line: for ce certification 250 micron stainless steel mesh, prioritize standard-backed mesh, traceable metallurgy, and testable aperture data. The paperwork matters almost as much as the wire.

References

- European Commission – CE marking and the Blue Guide (latest edition).

- ASTM E2016 – Standard Specification for Industrial Woven Wire Cloth.

- ISO 9044 – Industrial woven wire cloth – Technical requirements and tolerances.

- ASTM B117 – Standard Practice for Operating Salt Spray (Fog) Apparatus.

share

-

The Complete Guide to Decorative Mesh for B2B Decision Makers

NewsDec.08,2025

-

Weave Mesh Solutions for Industrial Applications | Wire Mesh BST

NewsDec.08,2025

-

Crimped Mesh: Durable, Versatile Metal Mesh for Global Industrial & Humanitarian Use

NewsDec.08,2025

-

Copper Mesh for Industrial Use – Reliable & Customizable Solutions

NewsDec.08,2025

-

Brass Mesh Solutions for Industry | Wiremeshbst.com Durable & Customizable

NewsDec.07,2025

-

Durable Wire Screen Solutions for Industrial Applications | WireMeshBST

NewsDec.07,2025