Sep . 15, 2025 07:40 Back to list

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

Introduction to Precision Stainless Steel Mesh

In industrial filtration, separation, and support applications, the integrity and performance of mesh materials are paramount. For critical operations, the demand extends beyond basic material specifications to include rigorous compliance and quality assurance. This article delves into the specifics of ce certification 250 micron stainless steel mesh, a highly specialized product crucial for applications demanding exceptional filtration efficiency, durability, and adherence to European safety standards. We explore its manufacturing intricacies, technical advantages, diverse applications, and the imperative role of CE certification in ensuring product reliability and market access.

The choice of stainless steel (primarily grades 304 and 316) provides inherent benefits, while the 250-micron aperture offers precision in separation. When coupled with CE certification, this material becomes a cornerstone for industries where performance cannot be compromised. Understanding its full lifecycle, from production to deployment, is essential for B2B decision-makers and engineers seeking optimal solutions.

Industry Trends & Market Dynamics

The global market for industrial wire mesh is experiencing consistent growth, driven by expansion in the petrochemical, food & beverage, pharmaceutical, and water treatment sectors. A significant trend is the increasing demand for certified products, particularly those meeting European CE standards. This is fueled by stricter regulatory environments and a growing emphasis on operational safety and product quality. Companies are moving away from uncertified generic materials to precision-engineered products like ce certification 250 micron stainless steel mesh to mitigate risks and ensure compliance.

Key drivers include advancements in manufacturing processes enabling finer and more uniform mesh, and the rising adoption of stainless steel for its superior corrosion resistance and hygiene properties. Furthermore, the push towards sustainable and energy-efficient operations has led to a preference for durable components that minimize downtime and replacement costs. The market also sees a rising demand for specialized mesh configurations, such as ce certification stainless steel wire mesh for screen printing, where precise aperture control is critical, and ce certification wire mesh ss 316, preferred for highly corrosive environments.

Technical Specifications & Material Science

Understanding the technical parameters of ce certification 250 micron stainless steel mesh is crucial for effective application. The "250 micron" specification refers to the nominal aperture size (opening between wires), indicating a very fine mesh suitable for precise separation. The material, typically AISI 304 or AISI 316 stainless steel, provides excellent mechanical properties and resistance to various forms of corrosion.

Stainless steel 304 (UNS S30400) is a common austenitic grade known for good corrosion resistance, formability, and weldability, making it versatile for general industrial applications. Stainless steel 316 (UNS S31600), on the other hand, contains molybdenum, which significantly enhances its resistance to pitting and crevice corrosion in chloride-rich environments and against various acids. This makes ce certification wire mesh ss 316 the material of choice for marine, chemical processing, and pharmaceutical industries.

Key Product Specifications: 250 Micron Stainless Steel Mesh

| Parameter | Specification (Typical for 250 Micron Mesh) |

|---|---|

| Material Grade | Stainless Steel 304, 316, 316L |

| Nominal Aperture Size | 250 microns (0.25 mm) |

| Wire Diameter | Typically 0.16 mm - 0.20 mm (varies with weave type) |

| Mesh Count (per inch) | Approximately 60-80 mesh/inch (depending on wire diameter) |

| Weave Type | Plain Weave, Twill Weave, Dutch Weave (Crimped for heavier gauges) |

| Open Area | Typically 30% - 40% (critical for flow rate and filtration efficiency) |

| Tensile Strength | 520-720 MPa (for SS304/316 wires) |

| Operating Temperature | Up to 800°C (SS304), 870°C (SS316) continuous |

| CE Certification | Conforms to essential health and safety requirements of relevant EU directives. |

The choice of weave type (plain, twill, Dutch, or crimped for larger apertures and enhanced stability) significantly impacts filtration characteristics, strength, and flow rates. For a 250-micron mesh, plain weave is common for precise filtration, offering a consistent pore size. Crimped weave, while more associated with coarser meshes, can be employed for specific structural rigidity requirements, influencing the overall performance of a ce certification heavy duty wire mesh application.

Manufacturing Process Flow for CE Certified 250 Micron Stainless Steel Mesh

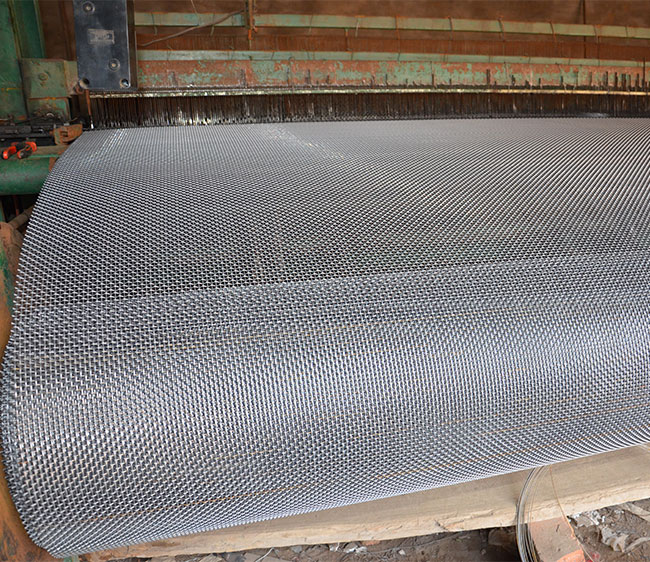

The production of high-quality, CE certified 250 micron stainless steel mesh involves a meticulously controlled process to ensure uniformity, durability, and adherence to stringent standards. Unlike casting or forging, wire mesh is manufactured through a weaving process, often starting with wire drawing and then precise weaving or crimping.

Schematic Steps:

- Raw Material Procurement & Inspection: High-grade stainless steel wire rods (e.g., AISI 304, 316) are sourced from certified suppliers. Incoming materials undergo stringent chemical composition analysis and mechanical testing (tensile strength, elongation) to ensure compliance with international standards like ASTM A276 or EN 10088. This step is critical for the base quality of ce certification 250 micron stainless steel mesh.

- Wire Drawing: The raw wire rods are drawn through a series of dies to achieve the precise wire diameter required for 250-micron mesh (typically 0.16mm - 0.20mm). This process enhances the wire's tensile strength and surface finish. In-line laser micrometers monitor diameter consistency.

- Annealing (Optional): Depending on desired flexibility and weave type, wires may undergo annealing to relieve internal stresses and optimize ductility for weaving.

-

Weaving/Crimping:

- Weaving: Precision weaving looms interlace warp (longitudinal) and weft (transverse) wires to create the mesh structure. For 250-micron aperture, plain weave is commonly used, ensuring consistent square openings. Advanced looms are computer-controlled to maintain precise mesh count and aperture dimensions across the entire roll.

- Crimping (for specific types): For specific applications, especially those requiring more robust and stable structures like ce certification square mesh wire fencing or certain ce certification heavy duty wire mesh, wires are pre-crimped (wavy) before weaving. This creates fixed intersections, enhancing rigidity and maintaining aperture size under stress. However, for 250 micron filtration, weaving typically achieves the precision needed.

- Edge Treatment & Finishing: After weaving, the mesh edges are often finished to prevent fraying and ensure safe handling. This can include selvage edges, welded edges, or trimmed edges, depending on the final application.

-

Quality Control & Testing: Each batch undergoes rigorous inspection, including:

- Aperture Size & Mesh Count Verification: Using optical comparators and precision calipers (e.g., ISO 9044).

- Wire Diameter Measurement: Using digital micrometers.

- Tensile Strength Testing: To confirm mechanical integrity of the woven structure (e.g., ASTM E8/E8M).

- Visual Inspection: For defects such as loose wires, uneven weave, or surface imperfections.

- Corrosion Resistance Testing: Salt spray tests or intergranular corrosion tests (for 316L) as per ISO 9227 or ASTM A262.

- CE Marking & Documentation: Upon successful testing and verification against relevant EU directives (e.g., Machinery Directive, Low Voltage Directive, etc., as applicable to the final product form), the product is CE marked. Comprehensive technical documentation, including Declaration of Conformity and user manuals, is prepared.

- Packaging & Dispatch: Finished mesh rolls are carefully packaged to prevent damage during transit, often with protective wrapping and robust cores, ready for delivery to target industries like petrochemical, metallurgy, and water supply & drainage.

The adherence to testing standards like ISO 9001 (Quality Management), ISO 9044 (Industrial wire screens — nominal sizes of openings and wire diameters), and in some cases, specific ANSI standards for screen performance, ensures the long-term service life and reliability of the mesh, demonstrating advantages in typical application scenarios like energy saving through efficient filtration and superior corrosion resistance in harsh environments.

Technical Advantages & Performance Metrics

The inherent properties of stainless steel, combined with the precision of a 250-micron aperture and the assurance of CE certification, bestow significant technical advantages upon this specialized mesh:

- Superior Corrosion Resistance: Stainless steel grades 304 and 316 offer excellent resistance to oxidation, general corrosion, and pitting, especially Grade 316 in aggressive chemical environments. This extends the service life of the mesh, reducing replacement frequency and maintenance costs, a key advantage for solutions like ce certification wire mesh ss 316.

- High Filtration Efficiency: The precise 250-micron aperture ensures consistent and effective particle separation, crucial for applications requiring fine filtration, such as in process fluid clarification, particle classification, and air purification systems. This precision is vital for creating a ce certification fine steel mesh screen.

- Exceptional Durability & Mechanical Strength: Woven stainless steel wire mesh exhibits high tensile strength and resistance to tearing and deformation, even under continuous operational stress and temperature fluctuations. This contributes to a long service life, typically ranging from 5 to 15 years depending on the application and environment.

- Temperature Stability: Stainless steel maintains its structural integrity and performance across a wide range of temperatures, from cryogenic conditions to elevated heat (up to 800-870°C), making it suitable for demanding industrial processes.

- Hygienic Properties & Easy Cleanability: The smooth, non-porous surface of stainless steel inhibits bacterial growth, making it ideal for pharmaceutical, food & beverage, and medical applications. It is also easy to clean and sanitize, supporting high cleanliness standards.

- CE Certification Assurance: This certification signifies compliance with the essential health and safety requirements of relevant European directives. It provides external validation of the product's quality, safety, and fitness for purpose, instilling confidence in B2B purchasers and facilitating market entry into the EU.

- Energy Saving Potential: In filtration systems, a consistently high-quality mesh like ce certification 250 micron stainless steel mesh can lead to more efficient flow rates, reduced pressure drop, and less frequent filter cleaning or replacement, indirectly contributing to energy savings and operational efficiency.

Application Scenarios & Target Industries

The versatility and high performance of ce certification 250 micron stainless steel mesh make it indispensable across a multitude of industries. Its precision and durability are leveraged in diverse applications, ranging from critical filtration to structural support.

- Petrochemical Industry: Used in catalytic cracking, fluid bed reactors, and distillation columns for precise particle separation, support grids, and in strainers to protect critical equipment from contaminants. Its corrosion resistance is vital in harsh chemical environments.

- Metallurgy & Mining: Employed in ore classification, slag removal, and as support for refractory linings. In powder metallurgy, it serves as a sieve for fine powder separation. The mesh's robustness ensures longevity in abrasive conditions, even for products like ce certification metal fine mesh used for critical sorting.

- Water Supply & Drainage / Wastewater Treatment: Integral to pre-filtration stages, sediment removal, and biological filter media support. The 250-micron mesh effectively screens out fine suspended solids, improving water quality and protecting downstream equipment.

- Food & Beverage Processing: Essential for sifting flour, filtering liquids (juices, oils), and as support trays in drying processes. The hygienic properties of stainless steel, coupled with CE compliance, ensure safety and prevent contamination. For example, in industrial kitchen settings, a ce certification stainless steel mesh box might be used for washing or drying delicate ingredients.

- Pharmaceuticals & Biotechnology: Utilized in tablet pressing, granular separation, active pharmaceutical ingredient (API) filtration, and as support for chromatography columns. The precision and inertness of stainless steel are critical for product purity and preventing batch contamination.

- Architecture & Construction: While often coarser meshes are used, 250-micron mesh can be found in specialized architectural elements for aesthetics or fine particle screening, and in high-security applications like ce certification wire mesh pool fencing where fine particle exclusion or specific visual characteristics are needed. More common are robust variants like ce certification stainless steel woven fabric for decorative or protective screens.

- Automotive & Aerospace: Used in fuel filters, oil strainers, air intake filters, and as spark arrestors, where robust filtration and resistance to high temperatures and corrosive fluids are critical.

These examples underscore the versatility and critical nature of this material, affirming its role in ensuring operational efficiency and product quality across diverse industrial landscapes.

Customized Solutions & Design Flexibility

While standard rolls of ce certification 250 micron stainless steel mesh meet many industrial needs, specialized applications frequently demand tailored solutions. Reputable manufacturers offer extensive customization capabilities to match exact client requirements, optimizing performance and integration.

- Material Grade Variations: Beyond 304 and 316, other stainless steel alloys (e.g., 316L, 321, 904L) can be supplied for extreme corrosion, high-temperature, or specific chemical resistance needs.

- Dimensions & Formats: Mesh can be supplied in custom roll widths and lengths, cut-to-size sheets, or fabricated into specific shapes such as discs, cylinders, or baskets (e.g., a custom ce certification stainless steel mesh box for unique applications).

- Weave Pattern Modifications: While 250-micron mesh commonly uses plain weave, specialized requirements might necessitate twill weave for increased strength or even Dutch weave for enhanced filtration capabilities and minimal pore size. Crimped wire mesh is primarily for larger apertures but can be combined for specific structural supports.

- Edge Treatments & Fabrication: Custom edge finishes, such as welded edges, folded edges, or rubber-coated edges, can be provided for improved durability, safety, and integration into existing systems. Manufacturers can also perform secondary fabrication processes like stamping, bending, and welding to create complex components.

- Surface Treatments: Electropolishing or passivation can enhance corrosion resistance, improve cleanliness, and reduce particle adhesion, crucial for sensitive applications.

Engaging with a manufacturer that offers robust engineering support and design consultation is key to developing optimal customized solutions. This ensures that the final product not only meets technical specifications but also aligns perfectly with operational demands and compliance requirements.

Vendor Comparison & Selection Criteria

Selecting the right vendor for ce certification 250 micron stainless steel mesh is a critical decision that impacts project success, cost-efficiency, and operational safety. B2B purchasers should evaluate suppliers based on a comprehensive set of criteria beyond just unit price.

Key Vendor Evaluation Parameters:

| Criterion | High-Quality, Certified Vendor | Standard/Generic Vendor |

|---|---|---|

| Certifications | CE Marking, ISO 9001, Material Traceability (Mill Certificates) | Limited or no specific product certifications; basic ISO (if any) |

| Product Consistency | Rigorous QC, tight tolerance control for aperture and wire diameter | Variable quality, wider tolerances, potential for weaving defects |

| Material Quality | Uses prime-grade stainless steel from reputable mills (e.g., for ce certification wire mesh ss 316) | May use recycled or lower-grade materials, affecting performance |

| Technical Support & Expertise | Offers engineering consultation, customized solutions, detailed data sheets | Limited technical assistance; off-the-shelf products only |

| Lead Time & Reliability | Consistent, predictable lead times; strong supply chain management | Inconsistent delivery, potential for delays due to quality issues or material sourcing |

| After-Sales Support & Warranty | Comprehensive warranty, responsive support, transparent return policy | Limited or no warranty, difficult dispute resolution |

| Cost-Effectiveness | Higher initial cost, but lower total cost of ownership (TCO) due to durability, performance, compliance | Lower initial cost, but higher TCO due to frequent replacements, downtime, and potential compliance issues |

Prioritizing suppliers with a proven track record, robust quality management systems (e.g., ISO 9001), and specific product certifications like CE is essential. A transparent vendor will readily provide mill certificates for raw materials and test reports for the finished product. This approach ensures not only compliance but also optimal long-term operational performance and safety.

Application Case Studies

Case Study 1: Fine Particle Separation in Chemical Processing

A leading chemical manufacturer required a highly precise and corrosion-resistant filtration medium for separating catalysts from a corrosive liquid mixture. Traditional mesh solutions were failing prematurely due to chemical attack and inconsistency in pore size, leading to product contamination and frequent downtime. They implemented a custom-fabricated ce certification 250 micron stainless steel mesh (SS316L grade) within their inline filtration units. The CE certification provided the necessary compliance for their European operations, while the precise 250-micron aperture ensured superior separation efficiency. After 18 months, the client reported a 70% reduction in equipment downtime and a significant improvement in catalyst recovery rates, attributing this directly to the durability and precise filtration capability of the certified mesh. The extended service life of the mesh also resulted in substantial energy savings by reducing the need for system restarts and cleanouts.

Case Study 2: Water Treatment Plant Micro-Screening

A municipal water treatment facility faced challenges with micro-algae and fine suspended solids bypassing their primary filtration systems, impacting the effectiveness of downstream UV disinfection. They adopted large panels of ce certification 250 micron stainless steel mesh as a micro-screening solution in their pre-treatment stage. The stainless steel 304 material offered excellent resistance to the chlorinated water, and the consistent 250-micron openings effectively captured the fine particulates. The CE certification was crucial for public procurement compliance. The outcome was a marked reduction in turbidity, less frequent backwashing of sand filters, and optimized performance of the UV disinfection units, leading to a 15% reduction in overall operational energy consumption for filtration and disinfection processes.

Quality Assurance, Certifications & Authoritativeness

Our commitment to quality is foundational, ensuring that every product, particularly ce certification 250 micron stainless steel mesh, meets the highest industry benchmarks. Our processes are governed by a comprehensive Quality Management System, certified to ISO 9001:2015 standards, which covers all aspects from raw material procurement to final dispatch.

- CE Certification: Our relevant products, including ce certification 250 micron stainless steel mesh, adhere to the essential health, safety, and environmental protection requirements as outlined by the European Directives. This involves rigorous conformity assessment procedures, ensuring products are safe and fit for purpose within the European Economic Area. This is a critical marker of our authoritativeness in the market.

- Material Traceability: We maintain full traceability for all raw materials, providing mill certificates (e.g., EN 10204 3.1) upon request. This ensures complete transparency regarding material composition and origin.

- Advanced Testing: In addition to standard QC, we utilize advanced testing methodologies such as optical microscopy for pore size analysis, scanning electron microscopy (SEM) for surface integrity, and energy dispersive X-ray spectroscopy (EDS) for precise material composition verification.

- Industry Accreditations: Beyond ISO 9001, our facilities and products adhere to specific industry standards and guidelines relevant to our target markets, ensuring broad acceptance and trust. Our long-standing partnerships with global industrial leaders, spanning over two decades, attest to our consistent quality and reliability.

Our commitment to these rigorous standards provides our clients with the assurance that they are investing in a product of unmatched quality, performance, and compliance.

Trustworthiness & Customer Support

Frequently Asked Questions (FAQ)

- Q: What is the primary benefit of CE certification for stainless steel mesh?

- A: CE certification signifies that the product meets the essential health, safety, and environmental protection requirements of relevant European Union directives. For industrial mesh, it ensures compliance for use within the EEA, providing a recognized standard of quality and safety for B2B purchasers.

- Q: Can 250 micron mesh be customized for specific applications?

- A: Absolutely. While 250 micron refers to the aperture size, aspects like material grade (e.g., SS304, SS316, 316L), dimensions (rolls, sheets, custom shapes), weave pattern, edge treatment, and even surface finishes (e.g., electropolishing) can be customized to meet precise operational and integration requirements.

- Q: What is the typical service life of CE certified 250 micron stainless steel mesh?

- A: The service life can vary significantly based on the application, environmental conditions (temperature, corrosive agents, abrasion), and maintenance regimen. However, with proper installation and use, high-quality stainless steel mesh can typically last from 5 to 15+ years in many industrial settings, far exceeding non-stainless or uncertified alternatives.

- Q: How does the "250 micron" specification relate to mesh count?

- A: Micron (µm) refers to the size of the opening (aperture), while mesh count is the number of openings per linear inch. For a 250 micron aperture, the mesh count typically falls between 60 to 80 mesh per inch, depending on the specific wire diameter used. A smaller wire diameter for a given aperture results in a higher open area and slightly higher mesh count, and vice versa.

Lead Time & Fulfillment

We understand the critical nature of timely delivery for industrial projects. Our standard lead times for common configurations of ce certification 250 micron stainless steel mesh typically range from 2-4 weeks, subject to order volume and current production schedules. For highly customized orders or large quantities, lead times will be provided upon detailed inquiry and are carefully managed through our project planning system. We maintain robust inventory levels of raw materials and popular finished goods to expedite urgent requests. Our logistics team works with trusted global carriers to ensure efficient and secure delivery worldwide.

Warranty & After-Sales Support

We stand behind the quality of our products with a comprehensive warranty against manufacturing defects and material failures under normal operating conditions. The specific warranty period and terms are provided with each quotation and order, typically ranging from 1 to 5 years, reflecting the expected performance and durability of our high-grade stainless steel mesh. Our dedicated customer support team is available to assist with any technical queries, installation guidance, or after-sales issues. We are committed to ensuring customer satisfaction and maximizing the operational lifespan of our products through expert advice and responsive service.

Conclusion

The implementation of ce certification 250 micron stainless steel mesh represents a strategic investment for B2B enterprises operating in demanding industrial environments. Its combination of precision filtration, superior material properties (SS304/316), and stringent CE compliance offers unparalleled reliability, extends service life, and ensures adherence to global safety and quality standards. By understanding the intricate manufacturing process, recognizing the diverse application potential, and prioritizing vendors committed to certified quality, industries can unlock significant operational efficiencies, reduce long-term costs, and maintain competitive advantages.

Choosing certified stainless steel mesh is not merely a purchase; it is a commitment to excellence and a proactive step towards future-proofing industrial operations against evolving regulatory landscapes and escalating performance demands.

References

- European Commission. (n.d.). CE marking. Retrieved from https://ec.europa.eu/growth/single-market/ce-marking_en

- ASTM International. (n.d.). ASTM Standards. Retrieved from https://www.astm.org/

- International Organization for Standardization. (n.d.). ISO 9001 - Quality management. Retrieved from https://www.iso.org/iso-9001-quality-management.html

- ASM International. (n.d.). ASM Handbook, Vol. 13A: Corrosion: Fundamentals, Testing, and Protection. Retrieved from https://www.asminternational.org/

- Outokumpu. (n.d.). Handbook of Stainless Steel. Retrieved from https://www.outokumpu.com/

share

-

The Complete Guide to Decorative Mesh for B2B Decision Makers

NewsDec.08,2025

-

Weave Mesh Solutions for Industrial Applications | Wire Mesh BST

NewsDec.08,2025

-

Crimped Mesh: Durable, Versatile Metal Mesh for Global Industrial & Humanitarian Use

NewsDec.08,2025

-

Copper Mesh for Industrial Use – Reliable & Customizable Solutions

NewsDec.08,2025

-

Brass Mesh Solutions for Industry | Wiremeshbst.com Durable & Customizable

NewsDec.07,2025

-

Durable Wire Screen Solutions for Industrial Applications | WireMeshBST

NewsDec.07,2025