Oct . 02, 2025 11:50 Back to list

Need Sintered Mesh with High Strength & Precise Filtration?

Field Notes on [sintered mesh]: What’s Moving the Market in 2025

If you spend enough time in filtration plants (I do, perhaps too much), you learn to tell which media quietly outlasts the rest. The unsung workhorse right now is sintered mesh—diffusion-bonded stainless wire layers that hold pore geometry even after countless backwashes. It’s not glamorous, but it’s dependable. And, to be honest, dependability is what keeps lines running at 3 a.m.

What it is (and why engineers love it)

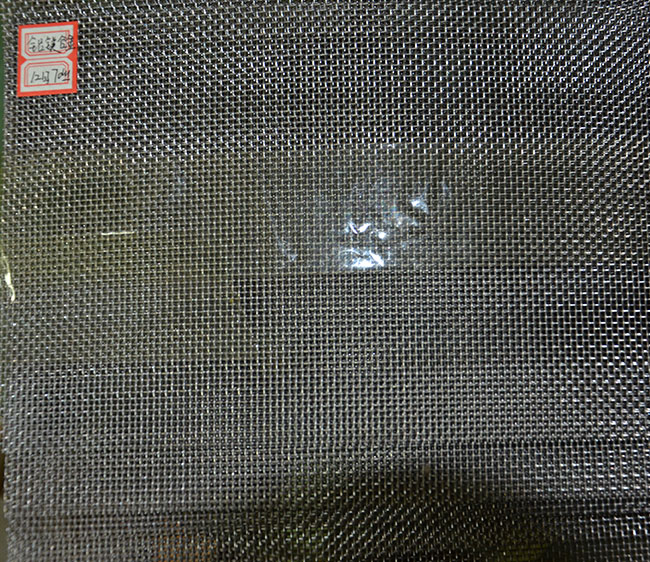

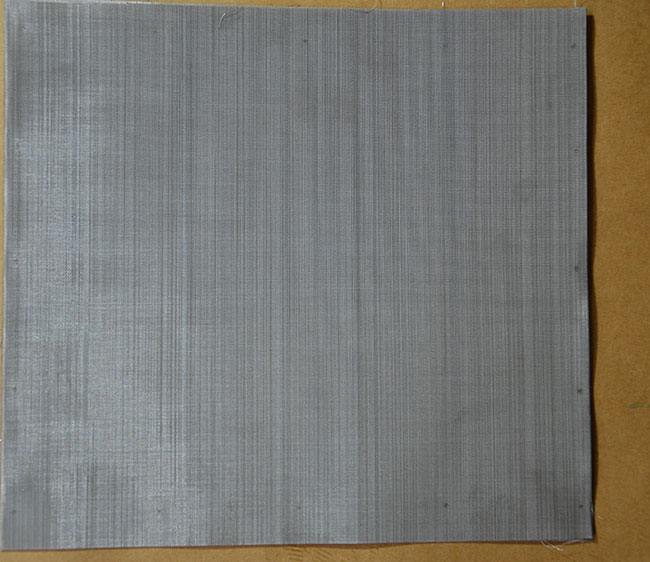

At its core, sintered mesh stacks multiple woven wire layers—often a protective layer, a control layer, and a support layer—then bonds them in a vacuum furnace. The result: fixed pore size, high permeability, and surprising crush strength. In real-world use, it means predictable pressure drop and fewer change-outs. Many customers say the stability after repeated CIP/SIP cycles is the clincher.

Typical process flow (shop-floor version)

- Materials: AISI 316/316L, 304/304L (plus black wire for certain support layers).

- Layer design: square weave + Dutch weave stacks, 2–7 layers depending on micron rating.

- Calendering and alignment: thickness control to ≈±0.05 mm on standard sheets.

- Vacuum/controlled-atmosphere sintering: typically 1050–1350°C; diffusion bonding across contact points.

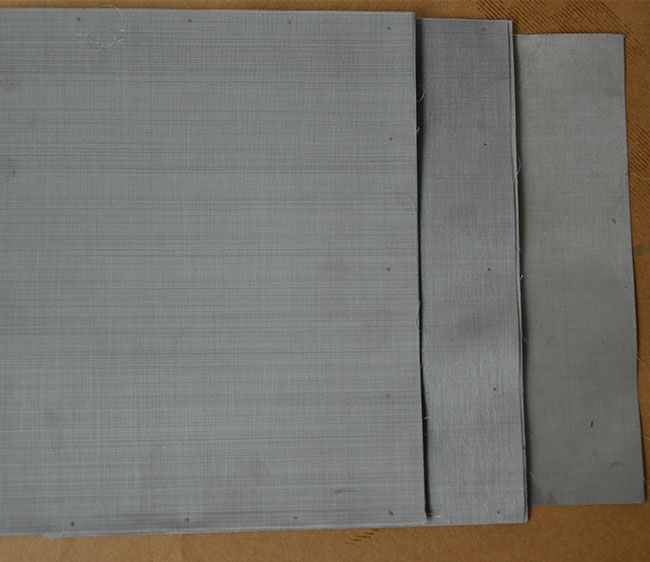

- Post-process: precision rolling, anneal if needed, laser/waterjet cutting into circle or square blanks (75–302 mm common).

- Testing: bubble-point (ASTM F316 / ISO 4003), permeability, burst, and corrosion screening (ASTM G48 for pitting, where applicable).

Product snapshot and specs

Origin: East Industry, Anping City, Hebei, China. Forms: circle, square, and custom. Sizes: 75, 133, 170, 230, 255, 302 mm (others on request).

| Parameter | Typical value (≈) |

|---|---|

| Materials | AISI 316/316L, 304/304L; black wire support |

| Layers | 2–7 |

| Micron rating | 1–200 μm (control layer defines cut) |

| Thickness | 0.5–3.5 mm |

| Porosity | 30–50% (stack dependent) |

| Max temperature | Up to 500°C in air; higher in inert gases |

| Differential pressure | Up to ≈3 MPa for discs; geometry dependent |

| Service life | 3–10 years with proper backwash/CIP |

| Certifications | ISO 9001:2015; material traceability available |

Quick lab note: a 10 μm sintered mesh disc (50 mm dia) at 25°C water showed initial ΔP ≈ 14–18 kPa at 5 L/min; after 20 backwash cycles ΔP drift was

Where it’s winning

- Petrochem & polymers: melt filtration, catalyst recovery.

- Water & wastewater: backwashable disc/candle elements.

- Food & beverage: clarification and gas sparging (316L favored).

- Pharma/biotech: prefiltration, vents with SIP resistance.

- Gas processing: guard filters at high ΔP/temperature.

Vendor landscape (quick comparison)

| Vendor | Origin | Certs | Micron range | Lead time | Customization |

|---|---|---|---|---|---|

| East Industry (Anping) | Hebei, China | ISO 9001 | ≈1–200 μm | 2–4 weeks | Shapes, layers, sizes (75–302 mm+) |

| Mott (reference) | USA | ISO 9001 | ≈0.2–100 μm | 4–6+ weeks | High-end custom assemblies |

| Porvair (reference) | UK/EU | ISO 9001 | ≈3–150 μm | 3–6 weeks | Industrial/regulated sectors |

Customization tips

When specifying sintered mesh, start with the solids PSD (D90), target β-ratio per ISO 16889, and allowable ΔP. Then pick layer stack and frame geometry. Edge welding, gasket grooves, and CIP chemistry (NaOH, peracetic, steam) should be decided early—saves headaches later.

Mini case studies

- Refinery guard filter: 25 μm stack cut maintenance by ~40% over 9 months; stable β10 ≥ 75 after multi-pass verification.

- Dairy clarification: 316L 5-layer discs survived 200+ SIP cycles; operators liked the easier backwash, surprisingly.

- Polymer melt line: 10 μm units ran hotter (280°C) without pore collapse; service life doubled vs. felt media.

Standards and references

- ASTM F316 – Standard Test Methods for Pore Size Characteristics of Membrane Filters.

- ISO 4003 – Metallic powders — Determination of pore size by bubble test.

- ISO 16889 – Hydraulic fluid power filters — Multi-pass method for evaluating filtration performance.

- ASTM E2016 – Standard Specification for Industrial Woven Wire Cloth.

- ASTM G48 – Pitting and crevice corrosion resistance of stainless steels.

share

-

The Complete Guide to Decorative Mesh for B2B Decision Makers

NewsDec.08,2025

-

Weave Mesh Solutions for Industrial Applications | Wire Mesh BST

NewsDec.08,2025

-

Crimped Mesh: Durable, Versatile Metal Mesh for Global Industrial & Humanitarian Use

NewsDec.08,2025

-

Copper Mesh for Industrial Use – Reliable & Customizable Solutions

NewsDec.08,2025

-

Brass Mesh Solutions for Industry | Wiremeshbst.com Durable & Customizable

NewsDec.07,2025

-

Durable Wire Screen Solutions for Industrial Applications | WireMeshBST

NewsDec.07,2025