Oct . 01, 2025 10:30 Back to list

ce certification 250 micron stainless steel mesh: why us?

A field note on sourcing ce certification 250 micron stainless steel mesh

I’ve spent enough time on factory floors in Anping to know: mesh is simple until it isn’t. The difference between a filter that hums along for years and one that clogs in a month often comes down to wire grade, weave accuracy, and—yes—documentation for CE. East Industry, Anping City, Hebei (the folks behind the Brass Mesh Filter line) quietly ships a lot of stainless filter pieces worldwide. The “brass” name is historical; most buyers today spec 304/316L for 250 μm apertures.

Quick product snapshot

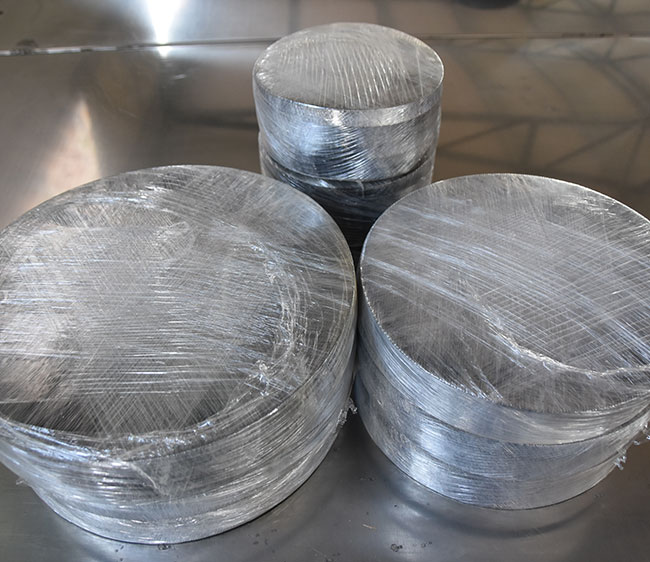

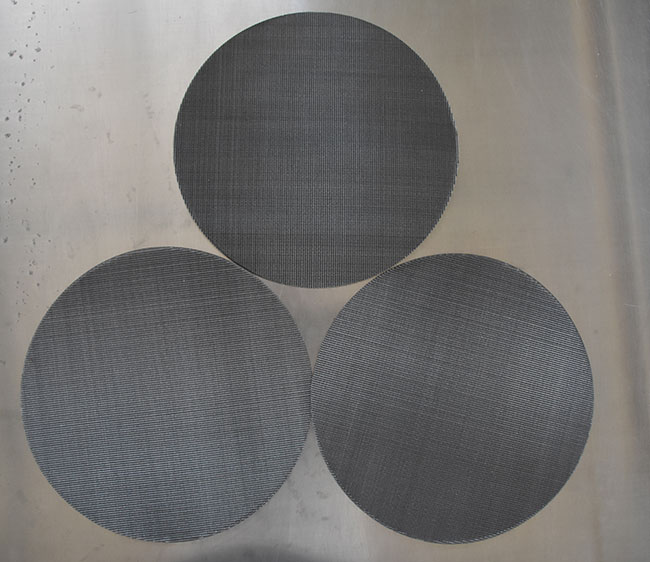

Product: Brass Mesh Filter (filter piece). Origin: East Industry, Anping, Hebei, China. Formats: circles/squares; standard diameters 75, 133, 170, 230, 255, 302 mm, or on inquiry. Materials: SS 304, 304L, 316, 316L (also black wire if you really want it, though I rarely recommend it for process lines).

| Parameter | Typical spec (≈, real-world use may vary) |

|---|---|

| Aperture | 250 μm (0.25 mm) |

| Approx. mesh count | ≈ 60–70 mesh |

| Wire diameter | ≈ 0.14–0.20 mm |

| Open area | ≈ 40–45% |

| Grades | SS 304/304L, 316/316L |

| Typical ΔP | Air @1 m/s: ≈ 2–5 mbar; Water @0.5 m/s: ≈ 5–15 kPa |

| Finish | Woven plain weave; deburred filter discs |

| Docs | EN 10204 3.1 MTC; CE conformity pack on request |

CE and the fine print (what really applies)

Mesh itself isn’t typically CE-marked as a standalone “article.” CE comes into play when the mesh is part of pressure equipment (PED 2014/68/EU), machinery (EU 2023/1230), or as a construction product (CPR) in certain assemblies. Pragmatically, buyers ask suppliers to support the CE file with: material certificates (EN 10204), dimensional and aperture verification per ISO 9044 / ASTM E2016, and a declaration of conformity when the mesh is integrated into a CE-marked assembly. Many customers say the documentation bundle saves days during audits.

Process flow and QC

- Materials: SS 316/316L or 304/304L wire, heat number–traceable; MTC per EN 10204 3.1.

- Weaving: plain weave to ISO 9044; target aperture 250 μm with ±5–8% tolerance (practical shop range).

- Cutting/forming: laser or die-cut discs (75–302 mm); deburr and ultrasonic clean if for food/pharma.

- Testing: aperture count via calibrated optics, thickness, open area estimation, salt spray (as specified), ΔP bench checks.

- Service life: in neutral media, 316L filters often run 3–7 years with CIP; aggressive chlorides shorten that—no surprise.

- Industries: polymer melt protection, edible oil, brewery hop filtration, coolant lines, HVAC pre-screens, lab sampling.

Vendor snapshot (comparing options)

| Vendor | Origin | Grades | CE file support | Lead time | Notes |

|---|---|---|---|---|---|

| East Industry (Anping) | Hebei, CN | 304/304L, 316/316L | MTC + ISO 9044/ASTM E2016 test sheet | 7–15 days | Cost-effective; consistent weave |

| Local fabricator | EU/US | 316L focus | Strong CE integration help | 2–4 weeks | Higher price; great traceability |

| Generic importer | Mixed | Varies | Inconsistent | Stock-dependent | Check aperture tolerance carefully |

Use cases and mini case studies

ce certification 250 micron stainless steel mesh in a craft brewery hop back: switching from 304 to 316L extended cleaning intervals from weekly to biweekly, thanks (mostly) to less pitting. In a polymer extrusion line, a 250 μm disc stack upstream of the gear pump cut gel defects by ≈18% (customer’s SPC data) with negligible ΔP increase. Another user in coolant filtration told me, almost sheepishly, that the biggest win was simply moving to laser-cut discs—flatness improved seal life.

Customization and ordering tips

- Shapes: circle and square are standard; odd geometries are doable with laser cutting.

- Sizes: 75–302 mm discs are off-the-shelf; ask for nested cutting to reduce scrap.

- Docs: request EN 10204 3.1, ISO 9044 aperture report, and a CE conformity note if your assembly needs it.

- Cleaning: specify ultrasonic pre-clean for food/pharma; it pays for itself, to be honest.

If you’re auditing suppliers, ask to see an ISO 9001 certificate, a recent optical aperture calibration log, and a template DoC referencing your end-use directive. It sounds fussy, but it saves back-and-forth later. And yes, ce certification 250 micron stainless steel mesh is mostly about correct paperwork combined with consistent weave.

Authoritative references

- ISO 9044:2016 Woven wire cloth for test sieves and industrial use. https://www.iso.org/standard/63796.html

- ASTM E2016-20 Standard Specification for Industrial Woven Wire Cloth. https://www.astm.org/e2016-20.html

- EN 10204:2004 Metallic products — Types of inspection documents. https://standards.iteh.ai/catalog/standards/cen/6f0f0b1c-…/en-10204-2004

- Directive 2014/68/EU (PED) and guidelines. https://single-market-economy.ec.europa.eu/sectors/pressure-equipment_en

- The “Blue Guide” on the implementation of EU product rules (2022). https://op.europa.eu/en/publication-detail/-/publication/cc4a1caa-f0e0-11ec-a534-01aa75ed71a1

share

-

The Complete Guide to Decorative Mesh for B2B Decision Makers

NewsDec.08,2025

-

Weave Mesh Solutions for Industrial Applications | Wire Mesh BST

NewsDec.08,2025

-

Crimped Mesh: Durable, Versatile Metal Mesh for Global Industrial & Humanitarian Use

NewsDec.08,2025

-

Copper Mesh for Industrial Use – Reliable & Customizable Solutions

NewsDec.08,2025

-

Brass Mesh Solutions for Industry | Wiremeshbst.com Durable & Customizable

NewsDec.07,2025

-

Durable Wire Screen Solutions for Industrial Applications | WireMeshBST

NewsDec.07,2025